things to draw with 3d pen packgout

Intro

In that location are three + i types of plastic that are used commonly for making 3D pen filaments. They take different looks and feels, dissimilar strength and flexibility contour, and different melting temperatures. (Generally speaking, the maximum temperature that a pen ca achieve is the primary determinant of what plastics it can utilise.)

The near common types of plastics are

- PLA or Polylactic Acid

- ABS or Acrylonitrile Butadiene Styrene

- FLEXY aka TPU or Thermoplastic Poly Urethane

- PCL or Poly Capro Lactone aka "low-temperature bioplastic"

The are less common filaments that also normally work in the temperature ranges of about pens: PET or PETG / PET-G or PolyEthylene Terephthalate Glycol-modified (these is what near non-biodegradable plastic bottles are fabricated of, and there'due south even a pen that tin direct recycle used plastic bottles) and HIPS (High Impact Poly Styrene).

And there are special filaments reserved for the more than "pro-grade" pens that can provide the high enough temperatures for working with them. Like Nylon and Polycarbonate (PC).

And since a picture is worth 1000 words:

(note that the "metal" and "carbon" filaments in the picture above are non bodily metallic or carbon – at that place are special mixes of PLA + actress ingredients or ABS + extra ingredients that give these looks)

…merely a table is worth 1000 pictures (below the table are the more in-depth descriptions).

3D Pen filament plastic types table

| | | | | | | |

|---|---|---|---|---|---|---|

| | | | | | - tin can look similar ice or glass | |

| | - low warp (adept for models that need to keep their shape without bending) | | | | | |

| | - great for pocket-size-kids-friendly low-temperature pens | | | | | - very plastic for a while after being drawn |

| | - no bad smells when heated (smells like popcorn!) | | - adhered too well to newspaper (use semi-glossy if you want to peel it off) - bonds to cloths (you tin draw on apparel and vesture them) | - most likely to snap when bent - less strong than ABS | - vulnerable to over-heating | - translucent options be - lots of special varieties exist (with-metal, wood-similar, conductive etc.) |

| | - even has a decent flex | | - easy to skin off materials such as paper (platonic for 3D pen stencils) | - bear on resistant and tough - has a decent flex to information technology | | - no translucent options - lots of special varieties be (with-metallic, wood-similar, conductive etc.) |

| | - one of the few usual filaments with decent transparency - should (but try at your own risk!) work with well-nigh ABS-compatible pens | | | | | - opaque varieties exist |

| | - flexible - low friction (can be smooth) | | | | | |

| | - very durable | | - bonds well to drinking glass - bonds badly to metals | - elastic | | - elastic |

PLA filaments

PLA or Polylactic acrid is called a bio-polymer because it's made from plant based materials (mostly corn based) and information technology biodegrades hands. It's a very popular material for 3D printing since it'svery like shooting fish in a barrel to 3D print with (flows easily, hardens fast), hasi of the lowest press temperatures (190-240°C / 374-464°F) that is still loftier enough to ensure the models go along their shape at room temperature, and on top of it it'snon-toxic anddoes not give off bad smells (when melted it smells somewhat like popcorn).

It's also afood condom plastic(but note that most 3D pen PLA filament areNon labeled as food prophylactic and they may comprise not-food-rubber additives and coloring sodo not utilize regular 3D pen PLA filaments for printing food recipients unless the filament is explicitly labeled "nutrient safe").

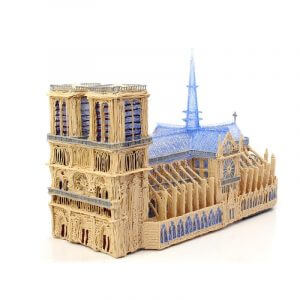

It has a glossier / shinier look than other plastics like ABS, and information technology also comes in translucent varieties. For example, the roofs and windows of this awesome looking model are drawn with PLA filament blazon while the rest is ABS:

There are lots of special options available, including semi transparent PLA (like the blue translucent one above), metal-like PLA, wood-like PLA, glow-in-the-dark PLA, conductive PLA plastic etc.

Information technology bonds well to cloth (so goof for cartoon on clothes), to other plastics similar ABS (so god for mixed drawings) and to paper (and then not ideal for stencils unless you use glossy paper).

Then far it sounds like theperfect 3D pen material, right? So why even bother with annihilation else? Well, it turns out that it has some drawbacks: information technology'due south brittle, less stiff than nigh other plastics, doesn't work so well for "drawing upward in the air", an it (bio)degrades when exposed to sunlight and moisture… great for biodegradable nutrient packaging, but not so keen for 3D models that you want tolast!

Read more most the strengths and weaknesses of PLA 3D pen filaments and when it'due south the right choice for your models in our dedicated commodity on PLA 3D pen filaments.

Pros

- eco-friendly (plant based and bio-degradable)

- no bad fumes and non-toxic

- translucent options available

Cons

- degrades when exposed to moisture and sunlight

- brittle

ABS filaments

ABS or Acrylonitrile butadiene styrene is one of the most common and versatile plastics. Chances are that your laptop / tablet or smartphone that you utilize to read this is at least partially made from ABS. Same for the lego bricks you've but stepped on. And most of the dashboard of your car!

It's fabricated from mostly petroleum based chemicals and it doesn't easily biodegrade, just it tin can exist easily recycled. When printing or drawing with information technology, it tends to give of some slightly unpleasant fumes, merely null also unpleasant. It tin give off toxic fumes when burnt (at over 400°C / 752°F – hint: your pen volition never ever get nearly this hot!) or when dissolved in acid (so continue those 3D doodled masterpieces away from the acid bath you always keep at hand!) But really, this matter is rubber: there'southward and then much ABS around yous that if information technology was really dangerous we'd all be already expressionless .

For 3D cartoon, ABS needs a slightly college temperature (225-250°C / 437-472°F) than PLA, this is why you need to alter the temperature setting on your pen. It offers one of thebest creative experiences since you lot tin "describe up in the air" with it after some practice, and the models also accept some flexibility to them. Information technology looks pretty sleeky, thought it'due south hart to tell apart PLA cloth from ABS from afar, and it comes in all imaginable varieties (glow-in-the dark, forest-similar, metallic-similar etc.) except transparent.

They alsolast, basically for-e'er if you don't go along them in directly sunlight or expose them to hot water.

Pros

- relatively strong and long lasting

- has some (limited) flexibility

Cons

- degrades with prolonged exposure to sunlight

- no translucent options

- gives of some fumes / odour when cartoon with it

Oh, and its chemical properties too open this up for some cool tricks (like using acetone to "polish" or to "chemically weld" ABS models after they've hardened) that yous tin read more most in our article dedicated to ABS plastic filaments.

FLEXY aka TPU/TPE (Thermoplastic polyurethane) filaments

The filaments unremarkably labeled FLEXY are actually a type of TPU/TPE (Thermoplastic polyurethane) plastic. They work at temperatures similar with ABS, so any ABS-compatible pen should as well work with FLEXY filaments.

What they bring is true flexibility andelasticity to 3D drawn models, unlocking a lot of extra creative potential! With these yous can depict things likeshoes orsmartphone cases orbracelets…you know, things that are actuallypractical to use and vesture, not just toys that sit down on a shelf somewhere.

Of course, this flexibility is not always what you need: lots of models actually demand to be rigid or to support weight. But when you need it, this filament isawesome.

Pros

- flexible and elastic

- durable

Cons

- less "special" filament options available and then far

- more expensive

- as well degrades with prolonged exposure to sunlight

PCL filaments

Polycaprolactone (PCL) is a non-toxic biodegradable polyester with a low melting point of around 60°C / 140°F. This makes it ideal for "kid friendly" low temperature 3D pens, and for DIY repair jobs that exploit the fact that it tin can be safely reshaped in hot water (hot enough to handle).

(Dwelling house-fabricated bicycle lite mounting, fabricated from PCL – from Wikipedia)

It also takes longer to solidify, making information technology easy to correct your drawing mistakes if yous're clumsy like me. And despite being softer, it still offers keen creative potential, assuasive yous to describe pretty complex and detailed models. Information technology's too dandy for stencils since it peels of easily from newspaper.

Pros

- depression melting point makes it kid-safe

- biodegradable and non-toxic

- does not bond to newspaper hands

Cons

- somewhat soft even afterward hardening – non good choice for weight begetting structures in models

- takes some time to harden, so it'due south somewhat hard to doodle up in the air with it

- non long lasting: melts in intense sunlight, degrades with prolonged exposure to sunlight and humidity

PETG / PET-One thousand filament

PETG / PET-Thousand or Polyethylene terephthalate glycol-modified, or it'southward cousin PET, is what most non-biodegradabe plastic bottles are made of. For 3D press or drawing you lot should use the "upgraded" glyco-modified variant PETG (sometimes also spelled PET-G).

This is a quite durable and strong plastic, and tends to bend or worst case tear, but non shatter. It'south stronger than ABS to both physical and chemical aggressions and prints at similar temperature. The drawing characteristics are a bit less pleasant than those of ABS – information technology'south a fleck "stringier" and less smooth-flowing, but information technology works pretty bang-up with some practice.

So if you lot want somethingstronger and more long-lasting than ABS that also hastransparent / translucent options bachelor, you should definitely look into PETG.

So areas where PETG shines because of good flexibility and forcefulness (so less weight needed for aforementioned shock-absorbing capacity) are things similar "bunpers" for drones:

Pros

- stronger than ABS (more flexible, less brittle, resistant to chemicals)

- lasts longer than ABS (as well less degraded past intense sunlight)

- transparent options available

Cons

- some say it's a bit more than annoying to draw with – though to be honest, the objections are mainly for press, where things like inter-layer adhesion and other such backdrop affair more than than for casual doodle-ing

- less special color options bachelor

HIPS filaments

HIPS or High Impact Polystyrene has backdropverylike to ABS, inlcuding drawing temperature (and so your ABS pens should support HIPS but fine). It's just slightly more towards the rigid and brittle side, which most of the time isnot what you want.

But it's less deformable, so it keeps information technology original shape even nether college load, which makes it meliorate for models with thin simply weight bearing structures. Some say it works better for things like 3D fatigued model airplanes since yous can become the same structural strength with less weight if handled properly.

Our communication is tosimply try information technology! You might like it more than than ABS, depending on the types of models you like to draw.

Pros

- relatively strong and long lasting

- deforms less than ABS

Cons

- degrades with prolonged exposure to sunlight

- no translucent options

Nylon (PA) filaments

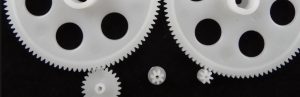

Nylon or PA (Polyamide) requires a higher press temperature than most pens on the market can handle. It's much stronger and durable than the plastics mentioned above, and it's besidesdepression friction… which is slap-up if you're using a 3D printer to make gears and bearings, but proably useless for 3D doodling with a pen, since the end consequence will be far from polish anyway.

Only if you lot really need highstrenght,endurance, somedecent flexibility andtransparent optionson top, and if your pen tin can handle it … then Nylon is great! Also, if you're making Nylon models on a 3D printer, you lot may want to Nylon-capabale 3D pen to tweak them.

Pros

- long lasting

- low friction

- high strength

- can be dyed

Cons

- high drawing temperature

PC (Polycarbonate) filaments

If you actually want to draw using the strongest materials out in that location, withthe stuff bullet-proof glass is fabricated from, PC is the manner to get. Information technology alwso requires the highest drawing temperature, with few pens getting close to it. It'southwardincredibly potent, and despite looking similar glass, it'southward waaay harder to break andshatter resistant.

Now, this may not audio like what anyone would need from a 3D pen filament… but there's more:

Polycarbonate is also great if you lot want things with a realistic glassy / ice-like / crystal-like await. I mean, aren't these gorgeous?

Pros

- very high strength

- long lasting

- glass-similar / ice-like advent

Cons

- high cartoon temperature

FAQ

What Filament Does 3d Pens Use?

3D pens use both PLA and ABS filaments, simply the most common one to use is PLA. PLA is more than suitable for 3D pens compared to other 3D filament types because it melts slowly and remains soft when used in a 3D pen.

Can 3d Pens Employ 3d Printer Filament?

The respond is yes, you can use the same filament that yous would employ in a 3D printer without the 3D pen. Only information technology'due south not always easy.

3d Pen Filament PLA vs ABS

Polylactic acid (PLA) can be used every bit a plastic that is meliorate for 3D printing than PLA. Because of its stiff characteristics, in that location are many uses where ABS is more suitable.

How to Have Filament Out of 3d Pen?

To remove melted plastic from a 3d pen, printing the push in the middle of the pen for two seconds. The melted plastic will run out of the pocket-sized hole at the end of the pen.

How Much Is Filament for a 3d Pen?

3D printing filaments cost around $25 on average. Some specialty 3D press filaments can cost up to four times this amount, and in that location are many other types of filaments that tin can be used in a diverseness of applications like plastic carving, jewelry making, and prototyping.

Which Filament Types and Colors Practise You Adopt to Use for Your 3d Prints?

I have tried a multifariousness of filaments, and prefer the PLA filaments. They are most often sold at cheaper prices than ABS or Nylon, and so I would opt for the ones with cheapest prices.

Which 3D Press Filament Is Dishwasher-condom?

ABS and other filaments like PETG can survive in dishwashers. They're heat-resistant. PLA on the other hand is not rut-resistant, so it'southward non prophylactic for utilize in dishwashers or other high temperatures.

Does 3D Printing Filament Incorporate Chemicals Such as BPA PVC

Most filaments are very fresh. This ways the plastic is non fully processed or will not cause nutrient bug. Some companies refine the plastic to make it easier to print, but should not crusade concern given that printing plastic is not intended for nutrient contact. That said, most filaments are not going to have BPA in them for the exact reason stated to a higher place.

Source: https://3dpenhub.com/3d-pen-filament-types/

0 Response to "things to draw with 3d pen packgout"

Post a Comment